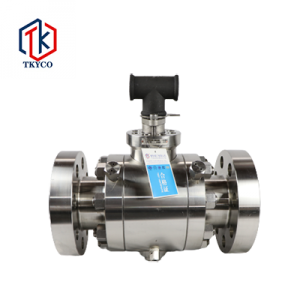

METAL SEAT (TEMPA) BALL VALVE

Ringkesan produk

Flange baja palsu jinis tutup werni tekanan dhuwur nutup bagean bal ing saubengé garis tengah awak tutup kanggo rotasi kanggo mbukak lan nutup tutup, segel ditempelake ing jog tutup stainless steel, jog tutup logam diwenehake karo spring, nalika lumahing sealing nyandhang utawa diobong, ing tumindak spring kanggo push jog tutup lan werni kanggo mbentuk segel logam. jog bali metu saka bal, entuk efek relief otomatis, sawise meksa relief tutup tutup otomatis reset, lan ditrapake kanggo banyu, solvent, asam lan gas, kayata medium karya umum, nanging uga cocok kanggo kahanan apa media, kayata oksigen, hidrogen peroksida, metana lan etilena, Iku wis Applied uga ing macem-macem industri.

Fitur struktur produk:

1. Kabeh bagean prodhuk iki forgings.

2, nggunakake batang tutup ngisor-dipasang, nyiyapake struktur sealing kuwalik, kanggo mesthekake yen packing Panggonan dipercaya sealing lan nyegah gagang metu.

3. Nganggo inlaid tutup seat.O-ring disetel konco jog tutup kanggo mesthekake yen medium ora bocor metu.

Struktur Produk

UKURAN UTAMA LUAR

(GB): PN40

| DN | L | D | D1 | D2 | b | f | n-d |

| 100 | 305 | 235 | 190 | 162 | 24 | 2 | 8-18 |

| 125 | 381 | 270 | 220 | 188 | 26 | 2 | 8-26 |

| 150 | 403 | 300 | 250 | 210 | 28 | 2 | 8-26 |

| 200 | 502 | 375 | 320 | 285 | 34 | 2 | 12-30 |

| 250 | 568 | 450 | 385 | 345 | 38 | 2 | 12-33 |

| 300 | 648 | 515 | 450 | 410 | 42 | 2 | 16-33 |

| 350 | 762 | 580 | 510 | 465 | 46 | 2 | 16-36 |

| 400 | 838 | 660 | 585 | 535 | 50 | 2 | 16-39 |

(GB): PN63

| DN | L | D | D1 | D2 | b | f | n-d |

| 100 | 406 | 250 | 200 | 162 | 30 | 2 | 8-26 |

| 125 | 432 | 295 | 240 | 188 | 34 | 2 | 8-30 |

| 150 | 495 | 345 | 280 | 218 | 36 | 2 | 8-33 |

| 200 | 597 | 415 | 345 | 285 | 42 | 2 | 12-36 |

| 250 | 673 | 47 | 400 | 345 | 46 | 2 | 12-36 |

| 300 | 762 | 530 | 460 | 410 | 52 | 2 | 16-36 |

| 350 | 826 | 600 | 525 | 465 | 56 | 2 | 16-39 |

| 400 | 902 | 670 | 585 | 535 | 60 | 2 | 16-42 |

(GB): PN100

| DN | L | D | D1 | D2 | b | f | n-d |

| 100 | 432 | 265 | 210 | 162 | 40 | 2 | 8-30 |

| 125 | 508 | 315 | 250 | 188 | 40 | 2 | 8-33 |

| 150 | 559 | 355 | 290 | 218 | 44 | 2 | 12-33 |

| 200 | 660 | 430 | 360 | 285 | 52 | 2 | 12-36 |

| 250 | 787 | 505 | 430 | 345 | 60 | 2 | 12-39 |

| 300 | 838 | 585 | 500 | 410 | 68 | 2 | 16-42 |

| 350 | 889 | 655 | 560 | 465 | 74 | 2 | 16-48 |

| 400 | 991 | 715 | 620 | 535 | 78 | 2 | 16-48 |

(ANSI): 300LB

| DN | L | D | D1 | D2 | b | f | n-d |

| 100 | 305 | 255 | 200 | 157.2 | 32.2 | 2 | 8-22 |

| 125 | 381 | 280 | 235 | 185.7 | 35.4 | 2 | 8-22 |

| 150 | 403 | 320 | 269.9 | 215.9 | 37 | 2 | 12-22 |

| 200 | 502 | 380 | 330.2 | 269.9 | 41.7 | 2 | 12-26 |

| 250 | 568 | 445 | 387.4 | 323.8 | 48.1 | 2 | 16-30 |

| 300 | 648 | 520 | 450.8 | 381 | 51.3 | 2 | 16-33 |

| 350 | 762 | 585 | 514.4 | 412.8 | 54.4 | 2 | 20-33 |

| 400 | 838 | 650 | 571.5 | 469.9 | 57.6 | 2 | 20-36 |

(ANSI): 600LB

| diameteripun nominal | L | D | D1 | D2 | b | f | n-d | |

| 4″ | 100 | 432 | 275 | 215.9 | 157.2 | 45.1 | 7 | 8-25 |

| 5″ | 125 | 508 | 330 | 266.7 | 185.7 | 51.5 | 7 | 8-30 |

| 6″ | 150 | 559 | 355 | 292.1 | 215.9 | 54.7 | 7 | 12-29 |

| 8″ | 200 | 660 | 420 | 349.2 | 269.9 | 62.6 | 7 | 12-32 |

| 10″ | 250 | 787 | 510 | 431.8 | 323.8 | 70.5 | 7 | 16-35 |

| 12″ | 300 | 838 | 560 | 489 | 381 | 73.7 | 7 | 20-35 |

| 14″ | 350 | 889 | 605 | 527 | 412.8 | 76.9 | 7 | 20-38 |

(ANSI): 900LB

| diameteripun nominal | L | D | D1 | D2 | b | f | n-d | |

| 4″ | 100 | 432 | 290 | 235 | 157.2 | 51.5 | 7 | 8-32 |

| 5″ | 125 | 508 | 350 | 279.4 | 185.7 | 57.8 | 7 | 8-36 |

| 6″ | 150 | 559 | 380 | 317.5 | 215.9 | 62.6 | 7 | 12-32 |

| 8″ | 200 | 660 | 470 | 393.7 | 269.9 | 70.5 | 7 | 12-38 |

| 10″ | 250 | 787 | 545 | 469.9 | 323.8 | 76.9 | 7 | 16-38 |

| 12″ | 300 | 838 | 610 | 533.4 | 381 | 86.4 | 7 | 20-38 |

| 14″ | 350 | 889 | 640 | 558.8 | 412.8 | 92.8 | 7 | 20-42 |

| 16″ | 400 | 991 | 705 | 616 | 469.9 | 95.9 | 7 | 20-45 |