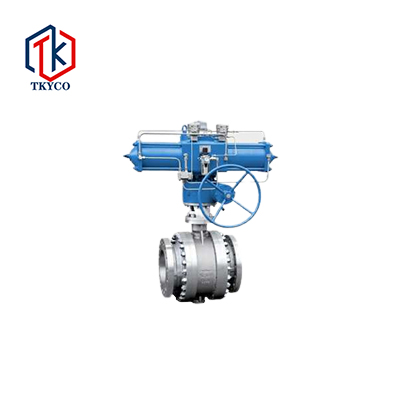

Metal Seat Ball Valve

Product Description

The driving part of the valve according to the valve structure and user requirements, using handle, turbine, electric, pneumatic, etc., can be based on the actual situation and user requirements to choose the appropriate driving mode.

This series of ball valve products according to the situation of medium and pipeline, and the different requirements of users, design of fire prevention, anti-static, such as structure, resistance to high temperature and low temperature can ensure valve under different conditions are often work, widely used in natural gas, oil, chemical industry, metallurgy, urban construction, environmental protection, pharmaceutical, food and other industries.

Features

• The series valves use forge steel or cast steel as their body material. The structure can be floating type or trunnion type ball supports.

• High precision machining results in superior ball and seat interfacing for tight shut off confomning to leakage standard of ANSI B16.104 dass VI.

• Flow direction for floating mounted type is uni-directional. Trunnion mounted type is fuly bi-directional with double-block-and-bleed capability.

• Dependable operations with low operating torque: Diaphragm spring loaded seat maintain close contact with the ball assuring tight sealing even at low pressure. This results in low opening and closing torques.

• Fire safe: The combination of metal seats and graphite seals insure fire-safe capabilities.

• The highest service applications temperature are up to 550°C (1022° F). The ball and seat hardened by spaceflight high-speed overlay. And hardness meets HRC 70-72.

• End connections:DIN or ANSI flange, butt weld or socket weld.

Floating Type Dimensions

|

Valve Size |

GB |

L |

ΦD |

ΦD1 |

N-h |

GB |

L |

ΦD |

ΦD1 |

N-h |

GB |

L |

ΦD |

ΦD1 |

N-h |

GB |

L |

ΦD |

ΦD1 |

N-h |

|

15 (1/2) |

16 |

130 |

95 |

65 |

4-14 |

25 |

130 |

95 |

65 |

4-14 |

40 |

130 |

95 |

65 |

4-14 |

64 |

165 |

105 |

75 |

4-14 |

|

20 (3/4) |

140 |

105 |

75 |

4-14 |

140 |

105 |

75 |

4-14 |

140 |

105 |

75 |

4-14 |

190 |

130 |

90 |

4-14 |

||||

|

25(1) |

140 |

115 |

85 |

4-14 |

140 |

115 |

85 |

4-14 |

150 |

115 |

85 |

4-14 |

216 |

140 |

100 |

4-14 |

||||

|

32 (1 1/4) |

165 |

140 |

100 |

4-18 |

165 |

140 |

100 |

4-18 |

180 |

140 |

100 |

4-18 |

229 |

155 |

110 |

4-22 |

||||

|

40 (1 1/2) |

165 |

150 |

110 |

4-18 |

165 |

150 |

110 |

4-18 |

200 |

150 |

110 |

4-18 |

241 |

170 |

125 |

4-22 |

||||

|

50(2) |

203 |

165 |

125 |

4-18 |

203 |

165 |

125 |

4-18 |

220 |

165 |

125 |

4-18 |

292 |

180 |

135 |

4-22 |

||||

|

65 ( 2 1/2) |

222 |

185 |

145 |

8-18 |

222 |

185 |

145 |

8-18 |

250 |

185 |

145 |

8-18 |

330 |

205 |

160 |

8-22 |

||||

|

80(3) |

241 |

200 |

160 |

8-18 |

241 |

200 |

160 |

8-18 |

280 |

200 |

160 |

8-18 |

356 |

215 |

170 |

8-22 |

||||

|

100 (4) |

280 |

220 |

180 |

8-18 |

280 |

235 |

190 |

8-22 |

320 |

235 |

190 |

4-22 |

432 |

250 |

200 |

8-26 |

||||

|

125 (5) |

320 |

250 |

210 |

8-18 |

320 |

270 |

220 |

8-26 |

400 |

270 |

220 |

8-26 |

508 |

295 |

240 |

8-30 |

||||

|

150 (6) |

360 |

285 |

240 |

4-22 |

360 |

300 |

250 |

8-26 |

400 |

300 |

250 |

8-26 |

559 |

345 |

280 |

8-33 |

||||

|

200 ( 8) |

457 |

340 |

295 |

12-22 |

457 |

360 |

310 |

12-22 |

457 |

375 |

320 |

12-30 |

660 |

400 |

345 |

12-36 |

|

Valve Size |

ANSI |

L |

ΦD |

ΦD1 |

N-h |

ANSI |

L |

ΦD |

ΦD1 |

N-h |

ANSI |

L |

ΦD |

ΦD1 |

N-h |

JISK |

L |

ΦD |

ΦD1 |

N-h |

|

15 (1/2) |

150 |

108 |

90 |

60.3 |

4-16 |

300 |

140 |

95 |

66.7 |

4-16 |

600 |

165 |

95 |

66.7 |

4-16 |

10K |

108 |

95 |

70 |

4-15 |

|

20 (3/4) |

117 |

100 |

69.9 |

4-16 |

152 |

115 |

82.6 |

4-19 |

190 |

115 |

82.6 |

4-19 |

117 |

100 |

75 |

4-15 |

||||

|

25(1) |

127 |

110 |

79.4 |

4-16 |

165 |

125 |

88.9 |

4-19 |

216 |

125 |

88.9 |

4-19 |

127 |

125 |

90 |

4-19 |

||||

|

32 (1 1/4) |

140 |

115 |

88.9 |

4-16 |

178 |

135 |

98.4 |

4-19 |

229 |

135 |

98.4 |

4-19 |

140 |

135 |

100 |

4-19 |

||||

|

40 (1 1/2) |

165 |

125 |

98.4 |

4-16 |

190 |

155 |

114.3 |

4-22.5 |

241 |

155 |

114.3 |

4-22.5 |

165 |

140 |

105 |

4-19 |

||||

|

50(2) |

178 |

150 |

120.7 |

4-19 |

216 |

165 |

127 |

8-19 |

292 |

165 |

127 |

8-19 |

178 |

155 |

120 |

4-19 |

||||

|

65 (2 1/2) |

190 |

180 |

139.7 |

4-19 |

241 |

190 |

149.2 |

8-22.5 |

330 |

190 |

149.2 |

8-22.5 |

190 |

175 |

140 |

4-19 |

||||

|

80(3) |

203 |

190 |

152.4 |

4-19 |

282 |

210 |

168.3 |

8-22.5 |

356 |

210 |

168.3 |

8-22.5 |

203 |

185 |

150 |

8-19 |

||||

|

100 (4) |

229 |

230 |

190.5 |

8-19 |

305 |

255 |

200 |

8-22.5 |

432 |

275 |

215.9 |

8-25.5 |

229 |

210 |

175 |

8-19 |

||||

|

125 (5) |

356 |

255 |

215.9 |

8-22.5 |

381 |

280 |

235 |

8-22.5 |

508 |

330 |

266.7 |

8-30 |

356 |

250 |

210 |

8-23 |

||||

|

150(6) |

394 |

280 |

241.3 |

8-22.5 |

403 |

320 |

269.9 |

12-22.5 |

559 |

355 |

292.1 |

12-30 |

394 |

280 |

240 |

8-23 |

||||

|

200 ( 8) |

457 |

345 |

298.5 |

8-22.5 |

502 |

380 |

330.2 |

12-25.5 |

660 |

420 |

349.2 |

12-33 |

457 |

330 |

290 |

12-23 |

GB

|

DN |

L |

PN16 |

D |

D1 |

D2 |

b |

f |

n-Φd |

PN25 |

D |

D1 |

D2 |

b |

f |

n-Φd |

PN40 |

L |

D |

D1 |

D2 |

b |

f |

n-Φd |

|

100 |

305 |

220 |

180 |

158 |

20 |

2 |

8-18 |

235 |

190 |

158 |

24 |

2 |

8-22 |

305 |

235 |

190 |

162 |

24 |

2 |

8-22 |

|||

|

125 |

356 |

250 |

210 |

188 |

22 |

2 |

8-18 |

270 |

220 |

188 |

26 |

2 |

8-26 |

381 |

270 |

220 |

188 |

26 |

2 |

8-26 |

|||

|

150 |

394 |

285 |

240 |

212 |

22 |

2 |

8-22 |

300 |

250 |

218 |

28 |

2 |

8-26 |

403 |

300 |

250 |

210 |

28 |

2 |

8-26 |

|||

|

200 |

457 |

340 |

295 |

268 |

24 |

2 |

12-22 |

360 |

310 |

278 |

30 |

2 |

12-26 |

502 |

375 |

320 |

285 |

34 |

2 |

12-30 |

|||

|

250 |

533 |

405 |

355 |

320 |

26 |

2 |

12-26 |

425 |

370 |

335 |

32 |

2 |

12-30 |

568 |

450 |

385 |

345 |

38 |

2 |

12-33 |

|||

|

300 |

610 |

460 |

410 |

378 |

28 |

2 |

12-26 |

485 |

430 |

395 |

34 |

2 |

16-30 |

648 |

515 |

450 |

410 |

42 |

2 |

16-33 |

|||

|

350 |

686 |

520 |

470 |

428 |

30 |

2 |

16-26 |

555 |

490 |

450 |

38 |

2 |

16-33 |

762 |

580 |

510 |

465 |

46 |

2 |

16-36 |

|||

|

400 |

762 |

580 |

525 |

490 |

32 |

2 |

16-30 |

620 |

550 |

505 |

40 |

2 |

16-36 |

838 |

660 |

585 |

535 |

50 |

2 |

16-39 |

|||

|

450 |

864 |

640 |

585 |

550 |

40 |

2 |

20-30 |

670 |

600 |

555 |

46 |

2 |

20-36 |

914 |

685 |

610 |

560 |

57 |

2 |

20-39 |

ANSI

|

in |

DN |

L |

150LB |

D |

D1 |

D2 |

b |

f |

n-Φd |

300LB |

D |

D1 |

D2 |

b |

f |

n-Φd |

600LB |

L |

D |

D1 |

D2 |

b |

f |

n-Φd |

|

4″ |

100 |

305 |

230 |

190.5 |

157.2 |

24 |

2 |

8-19 |

255 |

200 |

157.2 |

32 |

2 |

8-22 |

432 |

275 |

215.9 |

157.2 |

45.1 |

7 |

8-26 |

|||

|

5″ |

125 |

356 |

255 |

215.9 |

185.7 |

24 |

2 |

8-22 |

280 |

235 |

185.7 |

35 |

2 |

8-22 |

508 |

330 |

266.7 |

185.7 |

51.5 |

7 |

8-30 |

|||

|

6″ |

150 |

394 |

280 |

241.3 |

215.9 |

26 |

2 |

8-22 |

320 |

269.9 |

215.9 |

37 |

2 |

12-22 |

559 |

355 |

292.1 |

215.9 |

54.7 |

7 |

12-30 |

|||

|

8″ |

200 |

457 |

345 |

298.5 |

269.9 |

29 |

2 |

8-22 |

380 |

330.2 |

269.9 |

42 |

2 |

12-25 |

660 |

420 |

349.2 |

269.9 |

62.6 |

7 |

12-33 |

|||

|

10″ |

250 |

533 |

405 |

362 |

323.8 |

31 |

2 |

12-25 |

445 |

387.4 |

323.8 |

48 |

2 |

16-29 |

787 |

510 |

431.8 |

323.8 |

70.5 |

7 |

16-36 |

|||

|

12″ |

300 |

610 |

485 |

431.8 |

381 |

32 |

2 |

12-25 |

520 |

450.8 |

381 |

51.5 |

2 |

16-32 |

838 |

560 |

489 |

381 |

73.7 |

7 |

20-36 |

|||

|

14″ |

350 |

686 |

535 |

476.3 |

412.8 |

35.5 |

2 |

12-29 |

585 |

514.4 |

412.8 |

54.5 |

2 |

20-32 |

889 |

605 |

527 |

412.8 |

76.9 |

7 |

20-39 |

|||

|

16″ |

400 |

762 |

595 |

539.8 |

469.9 |

37 |

2 |

16-29 |

650 |

571.5 |

469.9 |

57.5 |

2 |

20-35 |

991 |

685 |

603.2 |

469.9 |

83.2 |

7 |

20-42 |

|||

|

18″ |

450 |

864 |

635 |

577.9 |

533.4 |

40 |

2 |

16-30 |

710 |

628.6 |

533.4 |

61 |

2 |

24-35 |

1092 |

745 |

654 |

533.4 |

89.6 |

7 |

20-45 |

JIS

|

DN |

L |

10K |

D |

D1 |

D2 |

b |

f |

n-Φd |

20K |

D |

D1 |

D2 |

b |

f |

n-Φd |

|

100A |

305 |

210 |

175 |

151 |

18 |

2 |

8-19 |

225 |

185 |

160 |

24 |

2 |

8-23 |

||

|

125A |

356 |

250 |

210 |

182 |

20 |

2 |

8-23 |

270 |

225 |

195 |

26 |

2 |

8-25 |

||

|

150A |

394 |

280 |

240 |

212 |

22 |

2 |

8-23 |

305 |

260 |

230 |

28 |

2 |

12-25 |

||

|

200A |

457 |

330 |

290 |

262 |

22 |

2 |

12-23 |

350 |

305 |

275 |

30 |

2 |

12-25 |

||

|

250A |

533 |

400 |

355 |

324 |

24 |

2 |

12-25 |

430 |

380 |

345 |

34 |

3 |

12-27 |

||

|

300A |

610 |

445 |

400 |

368 |

24 |

3 |

16-25 |

480 |

430 |

395 |

36 |

3 |

16-27 |

||

|

350A |

686 |

490 |

445 |

413 |

26 |

3 |

16-25 |

540 |

480 |

440 |

40 |

3 |

16-33 |

||

|

400A |

762 |

560 |

510 |

475 |

28 |

3 |

16-27 |

605 |

540 |

495 |

46 |

3 |

16-33 |

||

|

450A |

864 |

620 |

565 |

530 |

30 |

3 |

20-27 |

675 |

605 |

560 |

48 |

3 |

20-33 |