Products

-

Gb Flange, Wafer Butterfly Valve(Metal Seat, Soft Seat)

PRODUCT STANDARDS

■ Design standards: GB/T 12238

■ Face to Face: GB/T 12221

■ Flange end: GB/T 9113, JB/T 79, HG/T 20592

■ Test standards: GB/T 13927SPECIFICATIONS

■ Nominal pressure: PN0.6,1.0,1.6,2.5,4.0MPa

■ Shell test pressure: PT0.9,1.5, 2.4, 3.8, 6.0MPa

■ Low-pressure closure test: 0.6MPa

■ Suitable medium: water, oil, gas, acetic acid, nitric acid

■ Suitable temperature: -29℃~425℃

-

Manual / Pneumatic Knife Gate Valve

DESIGN & MANUFACTURE STANDARD

• Design and Manufacturing: JB/T8691, MSS SP-81

• Face-to-Face: GB/T15188.2, TAPPI TIS 405.8

• End flange: JB/F 79, ANSIB16.5, JIS B2220

• Inspection and testing: GB/T13927, MSS SP-81, JB/T8691Specifications

• Nominal pressure: 0.6.1.0.1.6Mpa

-Strength test: 0.9.1.5.2.4Mpa

• Seal test: 0.7.1,1.1.8Mpa

• Gas seal test: 0.6Mpa

-The valve main material: WCB(C), CF8(P), CF3(PL), CF8M(R), CF3M(RL)

• Suitable medium: Mortar mixture, Dregs with water proportion

• Suitable temperature: -29°C-100°C -

Ansi Flange, Wafer Butterfly Valve (Metal Seat, Soft Seat)

PRODUCT STANDARDS

• Design standards: API 609

• Face to Face: ASME B16.10

• Flange end: ASME B16.5

- Test standards: API 598

specifications

• Nominal pressure: Class 150/300

• Shell test pressure: PT3.0, 7.5MPa

• Low-pressure closure test: 0.6MPa

• Suitable medium: water, oil, gas, acetic acid, nitric acid

• Suitable medium: -29°C-425°C -

METAL SEAT (FORGED) BALL VALVE

Product Overview Forged steel flange type high pressure ball valve closing parts of the ball around the center line of the valve body for rotation to open and close a valve, the seal is embedded in the stainless steel valve seat, the metal valve seat is provided with a spring, when the sealing surface wear or burn, under the action of the spring to push the valve seat and the ball to form a metal seal.Exhibit unique automatic pressure release function, when the valve lumen medium pressure mor... -

Forged Steel Gate Valve

DESIGN & MANUFACTURE STANDARD

• Design and manufacture: API 602, ASME B16.34

• Connection ends dimension: ASME B1.20.1 and ASME B16.25

-Inspection test: API 598Specifications

-Nominal pressure: 150-800LB

• Strength test: 1.5xPN

• Seal test: 1.1xPN

• Gas seal test: 0.6Mpa

• Valve body material: A105(C), F304(P), F304L(PL), F316(R), F316L(RL)

• Suitable medium: water, steam, oil products, nitric acid, acetic acid

• Suitable temperature: -29°C-425°C -

Handle wafer butterfly valve

The middle line is clamped and sealed to ensure the two-way sealing of the valve.

Small torque, long service life

Detachable maintenance, convenient for later maintenance and replacement

-

Flange butterfly valve

Main Parts Material NO. Name Material 1 Body DI/304/316/WCB 2 Stem Stainless Steel 3 Material Stainless Steel 4 Butterfly plate 304/316/316L/DI 5 Coated rubber NR/NBR/EPDN MAIN SIZE AND WEIGHT DN 50 65 80 100 125 150 200 250 300 350 400 450 L 108 112 114 127 140 140 152 165 178 190 216 222 H 117 137 140 150 182 190 210 251 290 298 336 380 Hl 310 333 ... -

STAINLESS STEEL SANITARY CLAMPED U TYPE TEE-JOINT

Product Structure MAIN OUTER SIZE D1 D2 A B 2″ 1″ 200 170 2″ 2″ 200 170 2” 1 1/2″ 200 170 1 1/2″ 1″ 180 150 1 1/2″ 1″ 180 150 1 1/4″ 3/4″ 145 125 1″ 3/4″ 145 125 3/4″ 3/4″ 135 100 -

Manual Knife Gate Valve

Product Structure MAIN PARTS MATERIAL Part Name Material Body/Cover Carbon Sted.Stainless Sleel Fashboard Carbon Sleel.Stainless Steel Stem Stainless Steel Sealing Face Rubber.PTFE.Stainless Steel.CementedCarbide MAIN OUTER SIZE 1.0Mpa/1.6Mpa DN 50 65 80 100 125 150 200 250 300 350 400 450 500 600 700 800 900 DO 180 180 220 220 230 280 360 360 400 400 40 530 530 600 600 680 680 ... -

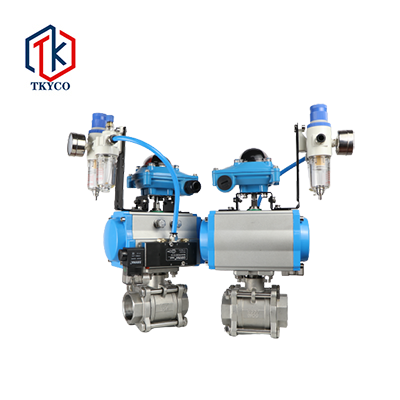

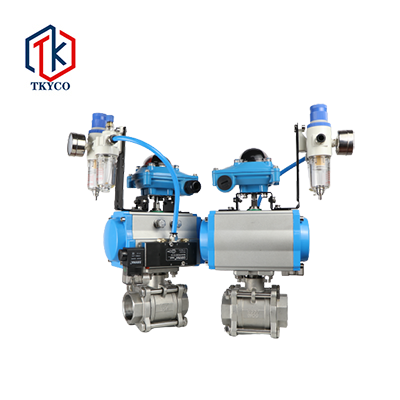

Pneumatic, Electric Actuator, Thread, Sanitary Clamped Ball Valve

Specifications

Nominal pressure: PN1.6-6.4, Class150/300,10k/20k

• Strength testing pressure: PT1.5PN

• Seat testing pressure(low pressure): 0.6MPa• Applicable temperature: -29°C-150°C

• Applicable media:

Q6 11/61F-(16-64)C Water. Oil. Gas

Q6 11/61F-(16-64)P Nitric acid

Q6 11/61F-(16-64)R Acetic acid -

Wafer Type Check Valve

Specircations

•Nominal pressure: PN1.6,2.5,4.0,6.4Mpa

•Strength testing pressure: PT2.4,3.8,6.0, 9.6MPa

•Seat testing pressure(high pressure): 1.8, 2.8, 4.4, 7.1 MPa

•Applicable media:

H?|H-(16-64)C Water. Oil. Gas

Hgw-(16-64)P Nitric acid

H^W-(16-64)R Acetic acid

•Applicable temperature: -29~150℃ -

Forged Check Valve

DESIGN&MANUFACTURE STANDARD

• Design&Manufacture: API 602, ASME B16.34

• Connection ends dimension as per:

ASME B1.20.1 and ASME B16.25

• Inspection and test as per:API 598specifications

-Nominal pressure: 150-800LB

• Strength testing pressure: 1.5xPN

• Seat test: 1.1xPN

• Gas seal test: 0.6Mpa

-The valve main material: A105(C), F304(P), F304L(PL), F316(R), F316L(RL)

• Suitable medium: water, steam, oil products, nitric acid, acetic acid

• Suitable temperature: -29℃-425℃