ANSI suzuvchi gardishli sharli vana

Mahsulotga umumiy nuqtai

Qo'lda gardishli sharsimon klapan asosan vositani kesish yoki o'tkazish uchun ishlatiladi, shuningdek suyuqlikni tartibga solish va nazorat qilish uchun ham ishlatilishi mumkin. Boshqa valflar bilan solishtirganda, shar klapanlari quyidagi afzalliklarga ega:

1, suyuqlik qarshiligi kichik, ball valfi barcha vanalarda eng kam suyuqlik qarshiligidan biridir, hatto u qisqartirilgan diametrli ball valf bo'lsa ham, uning suyuqlik qarshiligi juda kichik.

2, kalit tez va qulay, agar dastani 90 ° aylansa, sharsimon valf to'liq ochiq yoki to'liq yopiq harakatni yakunlaydi, tez ochilish va yopilishga erishish oson.

3, yaxshi sızdırmazlık ko'rsatkichi.Ball valve o'rindiqni muhrlash rishtasi odatda politetrafloroetilen va boshqa elastik materiallardan tayyorlangan bo'lib, muhrlanishni ta'minlash oson va ball valfining muhrlanish kuchi o'rta bosimning oshishi bilan ortadi.

4, valf ildizining muhrlanishi ishonchli. Bilye klapan ochilganda va yopilganda, valf novdasi faqat aylanadi, shuning uchun valf novdasining qadoqlash muhrini yo'q qilish oson emas va valfning teskari muhrining muhrlanish kuchi o'rta bosimning oshishi bilan ildiz ortadi.

5. Bilyali valfning ochilishi va yopilishi faqat 90 ° aylanishni amalga oshiradi, shuning uchun avtomatik boshqaruv va masofadan boshqarishga erishish oson. Bilye klapan pnevmatik qurilma, elektr moslama, gidravlik qurilma, gaz-suyuqlik ulash moslamasi yoki elektro-gidravlik aloqa moslamasi bilan sozlanishi mumkin.

6, balli vana kanali silliq, o'rtacha yotqizish oson emas, quvur liniyasi to'pi bo'lishi mumkin.

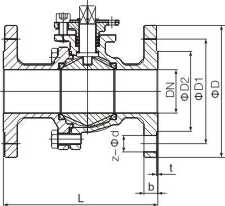

Mahsulot tuzilishi

ISO qonuni o'rnatish paneli

ISO yuqori o'rnatish paneli

asosiy qismlar va materiallar

| Material nomi | Karbonli po'lat | Zanglamaydigan po'lat | |

| Tana | WCB, A105 | CF8, CF3 | CF8M, CF3M |

| Kaput | WCB, A105 | CF8, CF3 | CF8M, CF3M |

| To'p | 304 | 304 | 316 |

| Poyasi | 304 | 304 | 316 |

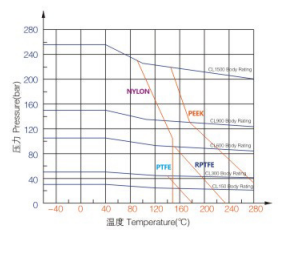

| O'rindiq | PTFE, RPTFE | ||

| Bezlarni qadoqlash | PTFE / Moslashuvchan grafit | ||

| Bez | WCB, A105 | CF8 | |

Asosiy hajmi va vazni

(ANSI): 150 LB

| in | DN | L | D | D1 | D2 | b | t | Z-Φd | ISO 5211 | XABAR |

| 1/2" | 15 | 108 | 90 | 60.3 | 34.9 | 10 | 2 | 4-16 | F03/F04 | 9X9 |

| 3/4" | 20 | 117 | 100 | 69.9 | 42.9 | 10.9 | 2 | 4- 16 | F03/F04 | 9X9 |

| 1" | 25 | 127 | 110 | 79.4 | 50.8 | 11.6 | 2 | 4-16 | F04/F05 | 11X11 |

| 1 1/4" | 32 | 140 | 115 | 88.9 | 63.5 | 13.2 | 2 | 4-16 | F04/F05 | 11X11 |

| 1 1/2" | 40 | 165 | 125 | 98.4 | 73 | 14.7 | 2 | 4-16 | F05/F07 | 14X14 |

| 2" | 50 | 178 | 150 | 120.7 | 92.1 | 16.3 | 2 | 4-19 | F05/F07 | 14X14 |

| 2 1/2" | 65 | 190 | 180 | 139.7 | 104.8 | 17.9 | 2 | 4-19 | F07 | 14X14 |

| 3" | 80 | 203 | 190 | 152.4 | 127 | 19.5 | 2 | 4-19 | F07/F10 | 17X17 |

| 4" | 100 | 229 | 230 | 190.5 | 157.2 | 24.3 | 2 | 8-19 | F07/F10 | 22X22 |

| 5" | 125 | 356 | 255 | 215.9 | 185.7 | 243 | 2 | 8-22 | ||

| 6" | 150 | 394 | 280 | 241.3 | 215.9 | 25.9 | 2 | 8-22 | ||

| 8" | 200 | 457 | 345 | 298.5 | 269,9 | 29 | 2 | 8-22 | ||

| 10" | 250 | 533 | 405 | 362 | 323.8 | 30.6 | 2 | 12-25 | ||

| 12" | 300 | 610 | 485 | 431,8 | 381 | 32.2 | 2 | 12-25 |

(ANSI): 300 LB

| in | DN | L | D | D1 | D2 | b | t | Z-Φd |

| 1/2" | 15 | 140 | 95 | 66.7 | 34.9 | 14.7 | 2 | 4-16 |

| 3/4" | 20 | 152 | 115 | 82.6 | 42.9 | 16.3 | 2 | 4-19 |

| 1" | 25 | 165 | 125 | 88.9 | 50.8 | 17.9 | 2 | 4-19 |

| 1 1/4" | 32 | 178 | 135 | 98.4 | 63.5 | 19.5 | 2 | 4-19 |

| 1 1/2" | 40 | 190 | 155 | 114.3 | 73 | 21.1 | 2 | 4-22 |

| 2" | 50 | 216 | 165 | 127 | 92.1 | 22.7 | 2 | 8-19 |

| 2 1/2" | 65 | 241 | 190 | 149.2 | 104.8 | 25.9 | 2 | 8-22 |

| 3" | 80 | 282 | 210 | 168.3 | 127 | 29 | 2 | 8-22 |

| 4" | 100 | 305 | 255 | 200 | 157.2 | 32.2 | 2 | 8-22 |

| 5" | 125 | 381 | 280 | 235 | 185.7 | 35.4 | 2 | 8-22 |

| 6" | 150 | 403 | 320 | 269,9 | 215.9 | 37 | 2 | 12-22 |

| 8" | 200 | 502 | 380 | 330.2 | 269,9 | 41.7 | 2 | 12-25 |

| 10" | 250 | 568 | 445 | 387.4 | 323.8 | 48.1 | 2 | 16-29 |

| 12" | 300 | 648 | 520 | 450,8 | 381 | 51.3 | 2 | 16-32 |

(ANSI): 600 LB

| in | DN | L | D | D1 | D2 | b | t | Z-Φd |

| 1/2" | 15 | 165 | 95 | 66.7 | 34.9 | 21.3 | 7 | 4-16 |

| 3/4" | 20 | 190 | 115 | 82.6 | 42.9 | 22.9 | 7 | 4-19 |

| 1" | 25 | 216 | 125 | 88.9 | 50.8 | 24.5 | 7 | 4-19 |

| 1 1/4" | 32 | 229 | 135 | 98.4 | 63.5 | 27.7 | 7 | 4-19 |

| 1 1/2" | 40 | 241 | 155 | 114.3 | 73 | 29.3 | 7 | 4-22 |

| 2" | 50 | 292 | 165 | 127 | 92.1 | 32.4 | 7 | 8-19 |

| 2 1/2" | 65 | 330 | 190 | 149.2 | 104.8 | 35.6 | 7 | 8-22 |

| 3" | 80 | 356 | 210 | 168.3 | 127 | 38.8 | 7 | 8-22 |

| 4" | 100 | 432 | 275 | 215.9 | 157.2 | 45.1 | 7 | 8-22 |

| 5" | 125 | 508 | 330 | 266.7 | 185.7 | 51.5 | 7 | 8-29 |

| 6" | 150 | 559 | 355 | 292.1 | 215.9 | 54.7 | 7 | 12-29 |

| 8" | 200 | 660 | 420 | 349.2 | 269,9 | 62.6 | 7 | 12-32 |

| 10" | 250 | 787 | 510 | 431,8 | 323.8 | 70.5 | 7 | 16-35 |

| 12" | 300 | 838 | 560 | 489 | 381 | 73.7 | 7 | 20-35 |

(ANSI): 900 LB

| in | DN | L | D | D1 | D2 | b | t | Z-Φd |

| 1" | 25 | 254 | 150 | 101.6 | 50.8 | 35.6 | 7 | 4-26 |

| 1 1/4" | 32 | 279 | 160 | 111.1 | 63.5 | 35.6 | 7 | 4-26 |

| 1 1/2" | 40 | 305 | 180 | 123.8 | 73 | 38.8 | 7 | 4-30 |

| 2" | 50 | 368 | 215 | 165.1 | 92.1 | 45.1 | 7 | 8-26 |

| 2 1/2" | 65 | 419 | 245 | 190.5 | 104.8 | 48.3 | 7 | 8-30 |

| 3" | 80 | 381 | 240 | 190.5 | 127 | 45.1 | 7 | 8-26 |

| 4" | 100 | 457 | 290 | 235 | 157.2 | 51.5 | 7 | 8-33 |