Yuqori samarali V sharli vana

Xulosa

V kesimi katta sozlanishi nisbati va teng foizli oqim xususiyatiga ega, bosim va oqimning barqaror nazoratini amalga oshiradi.

Oddiy tuzilish, kichik hajm, engil vazn, silliq oqim kanali.

O'rindiq va vilkaning muhrlangan yuzini samarali boshqarish va yaxshi muhrlanish ko'rsatkichlarini amalga oshirish uchun katta yong'oqning elastik avtomatik kompensatsiya tuzilishi bilan ta'minlangan. Eksantrik vilka va o'rindiq tuzilishi eskirishni kamaytirishi mumkin.

V kesim tolalarni o'z ichiga olgan muhitni o'chirish uchun o'rindiq bilan xanjar kesish kuchini ishlab chiqaradi. Bu, ayniqsa, yuqori viskoziteli muhit va tolalar va granulalarni o'z ichiga olgan vositalarni ochish va nazorat qilish uchun javob beradi.

Tana

• Turi: eksantrik burchakli sayohat integral to'pi, ko'ylagi to'pi

• Nominal diametri (DN): 1"~20"

• Nominal bosim (PN): ANSI 150LB-900LB

• Ulanish turi: gardishli ulanish yoki gofret turi

• Material: A216-WCB, A351-CF8, A351-CF8M (yoki zarb)

• Qadoqlash: PTFE singdirilgan asbest, PTFE, moslashuvchan grafit issiqlikni saqlaydigan ko'ylagi kelebek klapan ham foydalanuvchi talablariga muvofiq taklif qilinishi mumkin.

- Kesish

• Plug turi: V kesimli sharsimon sharsimon

• Shlangi materiali: A351-CF8, CF8M karbonlashtiruvchi yoki surfezli qattiq purkagich

• O'rindiq materiali va ish harorati:

Yumshoq muhr:

PTFE -20-+180 ℃

PTFE -20 - + 180 ℃ taqdim etilgan

PPL -40~+350℃

Qattiq muhr (y): A351-CF8, CF8M

karbonlashtiruvchi yoki sirt qattiq qotishma purkagichli payvandlash -40 + 450 ℃

Valf mili materiali: A276-420, A564-630

Yeng materiali: A182-F304, A182-F316 (nitridlash) yoki

WMS (yuqori haroratli qotishma)

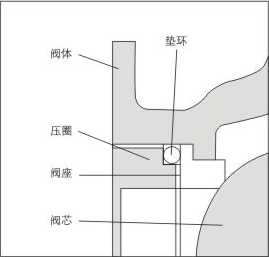

• 1-rasm Yumshoq muhr turi

Rozetka: A351-CF8, A351-CF8M

O'rindiq materiali: PTFE, to'ldirilgan PTFE, PPL

O'rindiqning oqishi: nol oqish

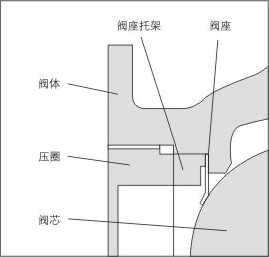

• 2-rasm Po'lat plitalar turi metall muhr

Shlangi materiali: A351-CF8, CF8M nitridlash yoki sirt purkagichli payvandlash

O'rindiq materiali: 3J1, Inconel zanglamaydigan po'latdan yasalgan qatlam

O'rindiqning oqishi: ANSI B16.104 sinf IV-VI muhrlanishi bo'yicha

KVx0,00l% (250°C) doirasida baholangan

KVx0,005% (400°C) doirasida baholangan

Mahsulot tuzilishi

igure 1 Yumshoq muhrning strukturaviy diagrammasi

Shakl 2 Po'lat plitalar turi metall qattiq muhr strukturaviy diagrammasi

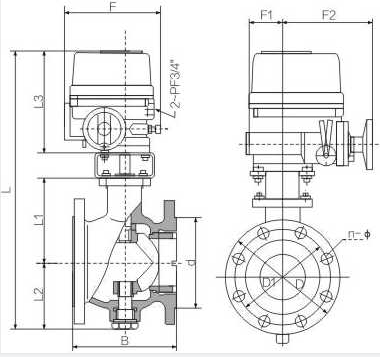

Chiqish va ulanish o'lchovlari

| DN | L | PN16 | L | 150 LB | 10K | |||||||||

| D | D1 | d | n-p | D | D1 | d | n-p | D | D1 | d | n-p | |||

| 25 | 450 | 115 | 85 | 65 | 4-14 | 102 | 110 | 79.4 | 50.8 | 4-16 | 125 | 90 | 67 | 4-19 |

| 32 | 470 | 140 | 100 | 76 | 4-18 | 102 | 115 | 88.9 | 63 | 4-16 | 135 | 100 | 76 | 4-19 |

| 40 | 473 | 150 | 110 | 84 | 4-18 | 114 | 125 | 98.4 | 73 | 4-16 | 140 | 105 | 81 | 4-19 |

| 50 | 488 | 165 | 125 | 99 | 4-18 | 124 | 150 | 1207 | 92.1 | 4-18 | 155 | 120 | 96 | 4-19 |

| 65 | 561 | 185 | 145 | 118 | 8-P18 | 145 | 180 | 139.7 | 104.8 | 4-18 | 175 | 140 | 116 | 4-19 |

| 80 | 586 | 200 | 160 | 132 | 8-P18 | 165 | 190 | 152.4 | 127 | 4-18 | 185 | 150 | 126 | 8-19 |

| 100 | 607 | 220 | 180 | 156 | 8-P18 | 194 | 230 | 190.5 | 157.2 | 8-18 | 210 | 175 | 151 | 8-19 |

| 125 | 668 | 250 | 210 | 184 | 8-P18 | 194 | 255 | 215.9 | 185.7 | 8-22 | 250 | 210 | 182 | 8-23 |

| 150 | 693 | 285 | 240 | 211 | 8-22 | 229 | 280 | 241.3 | 215.9 | 8-22 | 280 | 240 | 212 | 8-23 |

| 200 | 768 | 340 | 295 | 266 | 12-22 | 243 | 345 | 298.5 | 269,9 | 8-22 | 330 | 290 | 262 | 12-23 |

| 250 | 901 | 405 | 355 | 319 | 12-26 | 297 | 405 | 362 | 323.8 | 12-26 | 400 | 355 | 324 | 12-25 |

| 300 | 921 | 460 | 410 | 370 | 12-26 | 338 | 485 | 431,8 | 381 | 12-26 | 445 | 400 | 368 | 16-25 |

| 350 | 1062 | 520 | 470 | 429 | 16-29 | 400 | 535 | 476.3 | 412.8 | 12-30 | 490 | 445 | 413 | 16-25 |

| 400 | 1117 | 580 | 525 | 480 | 16-30 | 400 | 595 | 539,8 | 469,9 | 16-30 | 560 | 510 | 475 | 16-27 |

| 450 | 1255 | 640 | 585 | 548 | 20-30 | 520 | 635 | 577,9 | 533.4 | 16-33 | 620 | 565 | 530 | 20-27 |

| 500 | 1282 | 715 | 650 | 609 | 20-33 | 600 | 700 | 635 | 584.2 | 20-33 | 675 | 620 | 585 | 20-27 |