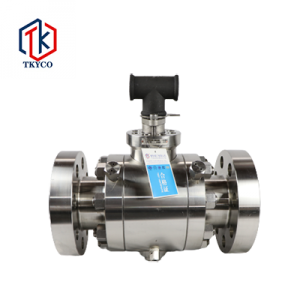

METAL o'rindiqli (zarb qilingan) sharli klapan

Mahsulotga umumiy nuqtai

Soxta po'lat gardish tipidagi yuqori bosimli sharli klapan valfni ochish va yopish uchun aylanish uchun valf tanasining markaziy chizig'i atrofidagi to'pni yopish qismlari, muhr zanglamaydigan po'latdan yasalgan valf o'rindig'iga o'rnatilgan, metall valf o'rindig'i bahor bilan ta'minlangan. , Sızdırmazlık yuzasi eskirganda yoki yonib ketganda, bahor ta'sirida valf o'rindig'ini surish va to'pni metall muhr hosil qilish uchun. Noyob avtomatik bosimni bo'shatish funktsiyasini ko'rsating, vana lümeni o'rta bosimi bahordan ko'proq bo'lganda Oldindan siqish kuchi, chiqish klapanining o'rindig'i shardan chiqib, avtomatik relyef effektiga erishing, bosim o'tkazuvchi valf o'rindig'ini avtomatik ravishda qayta o'rnatgandan so'ng va umumiy ish muhiti kabi suv, erituvchi, kislota va gazga qo'llaniladi, lekin ayni paytda mos keladi. kislorod, vodorod periks, metan va etilen kabi ommaviy axborot vositalarining ish sharoitlari, turli sohalarda yaxshi qo'llanilgan.

Mahsulot tuzilishi xususiyatlari:

1. Ushbu mahsulotning barcha qismlari zarb qilingan.

2, pastki qismga o'rnatilgan valf poyasidan foydalanish, qadoqlash ishonchli muhrlanishini ta'minlash va dastani chiqib ketishining oldini olish uchun teskari muhrlangan strukturani o'rnating.

3. Inklyuziv klapan o'rindig'ini qabul qiling. O-ring valf o'rindig'ining orqasida vosita oqmasligi uchun o'rnatiladi.

Mahsulot tuzilishi

ASOSIY tashqi o'lchami

(GB): PN40

| DN | L | D | D1 | D2 | b | f | n-Φd |

| 100 | 305 | 235 | 190 | 162 | 24 | 2 | 8-18 |

| 125 | 381 | 270 | 220 | 188 | 26 | 2 | 8-26 |

| 150 | 403 | 300 | 250 | 210 | 28 | 2 | 8-26 |

| 200 | 502 | 375 | 320 | 285 | 34 | 2 | 12-30 |

| 250 | 568 | 450 | 385 | 345 | 38 | 2 | 12-33 |

| 300 | 648 | 515 | 450 | 410 | 42 | 2 | 16-33 |

| 350 | 762 | 580 | 510 | 465 | 46 | 2 | 16-36 |

| 400 | 838 | 660 | 585 | 535 | 50 | 2 | 16-39 |

(GB): PN63

| DN | L | D | D1 | D2 | b | f | n-Φd |

| 100 | 406 | 250 | 200 | 162 | 30 | 2 | 8-26 |

| 125 | 432 | 295 | 240 | 188 | 34 | 2 | 8-30 |

| 150 | 495 | 345 | 280 | 218 | 36 | 2 | 8-33 |

| 200 | 597 | 415 | 345 | 285 | 42 | 2 | 12-36 |

| 250 | 673 | 47 | 400 | 345 | 46 | 2 | 12-36 |

| 300 | 762 | 530 | 460 | 410 | 52 | 2 | 16-36 |

| 350 | 826 | 600 | 525 | 465 | 56 | 2 | 16-39 |

| 400 | 902 | 670 | 585 | 535 | 60 | 2 | 16-42 |

(GB): PN100

| DN | L | D | D1 | D2 | b | f | n-Φd |

| 100 | 432 | 265 | 210 | 162 | 40 | 2 | 8-30 |

| 125 | 508 | 315 | 250 | 188 | 40 | 2 | 8-33 |

| 150 | 559 | 355 | 290 | 218 | 44 | 2 | 12-33 |

| 200 | 660 | 430 | 360 | 285 | 52 | 2 | 12-36 |

| 250 | 787 | 505 | 430 | 345 | 60 | 2 | 12-39 |

| 300 | 838 | 585 | 500 | 410 | 68 | 2 | 16-42 |

| 350 | 889 | 655 | 560 | 465 | 74 | 2 | 16-48 |

| 400 | 991 | 715 | 620 | 535 | 78 | 2 | 16-48 |

(ANSI): 300 LB

| DN | L | D | D1 | D2 | b | f | n-Φd |

| 100 | 305 | 255 | 200 | 157.2 | 32.2 | 2 | 8-22 |

| 125 | 381 | 280 | 235 | 185.7 | 35.4 | 2 | 8-22 |

| 150 | 403 | 320 | 269,9 | 215.9 | 37 | 2 | 12-22 |

| 200 | 502 | 380 | 330.2 | 269,9 | 41.7 | 2 | 12-26 |

| 250 | 568 | 445 | 387.4 | 323.8 | 48.1 | 2 | 16-30 |

| 300 | 648 | 520 | 450,8 | 381 | 51.3 | 2 | 16-33 |

| 350 | 762 | 585 | 514.4 | 412.8 | 54.4 | 2 | 20-33 |

| 400 | 838 | 650 | 571,5 | 469,9 | 57.6 | 2 | 20-36 |

(ANSI): 600 LB

| Nominal diametri | L | D | D1 | D2 | b | f | n-Φd | |

| 4″ | 100 | 432 | 275 | 215.9 | 157.2 | 45.1 | 7 | 8-25 |

| 5 dyuym | 125 | 508 | 330 | 266.7 | 185.7 | 51.5 | 7 | 8-30 |

| 6 ″ | 150 | 559 | 355 | 292.1 | 215.9 | 54.7 | 7 | 12-29 |

| 8 dyuym | 200 | 660 | 420 | 349.2 | 269,9 | 62.6 | 7 | 12-32 |

| 10 ″ | 250 | 787 | 510 | 431,8 | 323.8 | 70.5 | 7 | 16-35 |

| 12 dyuym | 300 | 838 | 560 | 489 | 381 | 73.7 | 7 | 20-35 |

| 14 dyuym | 350 | 889 | 605 | 527 | 412.8 | 76.9 | 7 | 20-38 |

(ANSI): 900 LB

| Nominal diametri | L | D | D1 | D2 | b | f | n-Φd | |

| 4″ | 100 | 432 | 290 | 235 | 157.2 | 51.5 | 7 | 8-32 |

| 5 dyuym | 125 | 508 | 350 | 279.4 | 185.7 | 57.8 | 7 | 8-36 |

| 6 ″ | 150 | 559 | 380 | 317.5 | 215.9 | 62.6 | 7 | 12-32 |

| 8 dyuym | 200 | 660 | 470 | 393,7 | 269,9 | 70.5 | 7 | 12-38 |

| 10 ″ | 250 | 787 | 545 | 469,9 | 323.8 | 76.9 | 7 | 16-38 |

| 12 dyuym | 300 | 838 | 610 | 533.4 | 381 | 86.4 | 7 | 20-38 |

| 14 dyuym | 350 | 889 | 640 | 558,8 | 412.8 | 92.8 | 7 | 20-42 |

| 16 dyuym | 400 | 991 | 705 | 616 | 469,9 | 95.9 | 7 | 20-45 |